The Importance of PDN Measurement in Ensuring Reliable Power Delivery to Your PCBs

Are you tired of dealing with power issues that plague your printed circuit boards (PCBs)? Frustrated by unpredictable failures and costly reworks? It’s time to put an end to these woes and ensure a smooth power delivery system for your PCBs. In this blog post, we delve into the critical importance of PDN measurement in guaranteeing reliable power distribution throughout your electronic devices. So, fasten your seatbelts as we embark on a journey to uncover the secrets behind seamless power delivery – no more guessing games or compromises!

Introduction to Power Delivery Network (PDN) Measurement

As electronic systems have become more complex, the need for reliable power delivery has increased. The power delivery network (PDN) is responsible for delivering power to all the components on a PCB. If the PDN is not functioning properly, it can cause problems with the operation of the electronic system.

One way to ensure that the PDN is working properly is to measure it. Measurement of the PDN can reveal problems that may not be apparent otherwise. It can also help to optimize the design of the PDN so that it delivers power more efficiently.

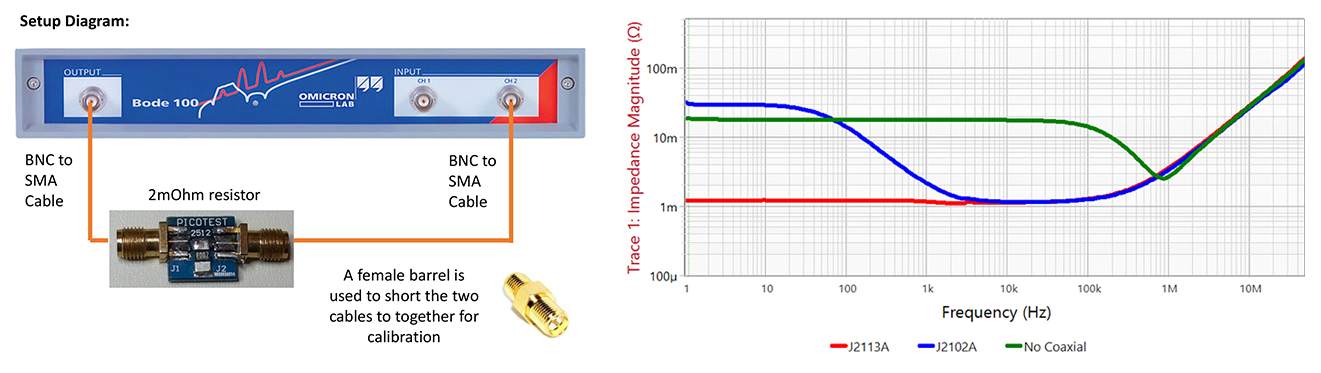

There are many different ways to measure the PDN. Some common methods include voltage measurements, current measurements, and impedance measurements. Each of these methods has its own advantages and disadvantages. Voltages can be measured using a voltmeter, while currents can be measured using an ammeter or a current probe. Impedance can be measured using an impedance meter or an oscilloscope.

No matter which method you use, it is important to make sure that you are taking accurate readings. This means calibrating your instruments before making any measurements. It is also important to take multiple readings at different points in time so that you can see how the PDN changes over time.

By understanding how to measure the PDN, you can ensure that your electronic system receives reliable power delivery. This will help to improve the performance of your system and reduce the risk of problems occurring

Benefits of PDN Measurement

As electronic designs become more complex, the power delivery network (PDN) becomes increasingly important. The PDN is responsible for supplying power to all the components on a PCB, and it is vital that it operates reliably.

One of the most important aspects of ensuring reliable PDN operation is accurate measurement. By measuring the voltage and current at various points in the PDN, engineers can build up a picture of how it is performing. This allows them to identify any potential problems and take steps to fix them before they cause any damage or downtime.

There are many benefits to accurate PDN measurement, including:

1. Reduced risk of component damage: If the PDN is not delivering enough power to a particular component, this can lead to that component being damaged. By measuring the power delivery at various points in the network, engineers can ensure that components are getting the power they need.

2. Increased system reliability: A well-functioning PDN is vital for ensuring reliable system operation. By taking measurements throughout the PDN, engineers can be sure that it is operating as intended and make any necessary adjustments if it isn’t.

3. Improved design quality: Measuring the PDN helps engineers to understand how different design choices affect performance. This knowledge can then be used to improve future designs.

4. Cost savings: By identifying potential problems early on, accurate PDN measurement can help to save money by avoiding costly repairs or replacements down

Types of PDN Measurement

There are three main types of PDN measurement: impedance, crosstalk, and noise.

1. Impedance measurement is used to determine the overall resistance of the power delivery network. This is important in order to ensure that the correct amount of power is being delivered to the PCB.

2. Crosstalk measurement is used to determine the amount of interference between different signal lines in the power delivery network. This is important in order to ensure that signals are not being corrupted by other signals in the PDN.

3. Noise measurement is used to determine the amount of noise present in the power delivery network. This is important in order to ensure that the PDN is not introducing any unwanted noise into the system.

How Does PDN Measurement Work?

When it comes to ensuring reliable power delivery to your PCBs, one of the most important things you can do is to measure the PDN. This will help you identify potential problems and correct them before they cause any damage.

There are a few different ways to measure PDN, but the most common is by using a multimeter. To do this, you’ll need to connect the positive lead of the multimeter to the positive PDN terminal on your PCB, and the negative lead to the ground terminal. Once you have everything hooked up, you can simply take a reading from the multimeter.

Keep in mind that PDN measurement is just one tool that you can use to ensure reliable power delivery to your PCBs. There are other factors that you’ll need to consider as well, such as voltage ripple and current noise. But if you take care of the PDN measurement, you’ll be well on your way to ensuring that your PCBs receive clean and reliable power.

Common Challenges with PDN Measurement

As the demand for smaller, more powerful electronic devices continues to grow, so does the need for reliable power delivery networks (PDNs). While PDNs play a vital role in ensuring the proper functioning of electronic devices, they can also be one of the most challenging aspects of PCB design and manufacturing.

One of the most common challenges with PDN measurement is obtaining accurate and repeatable measurements. This can be difficult due to the many variables that can affect measurements, such as board thickness, component placement, and trace width.Another challenge is measuring PDNs with high impedance levels. This is often necessary when dealing with high-speed digital circuits or sensitive analog circuits. However, measuring high impedance levels can be difficult and requires special equipment and expertise.

Another common challenge with PDN measurement is dealing with crosstalk. Crosstalk is a phenomenon whereby signals from one circuit element interfere with other nearby circuit elements. Crosstalk can occur between traces on a single layer or between different layers of a multilayer board. It can also occur between different PDNs on a single board or between multiple boards in a system. Crosstalk can be difficult to measure and may require special test equipment and techniques.

Best Practices for Ensuring Reliable Power Delivery to Your PCBs

There are a few best practices that can help ensure reliable power delivery to your PCBs:

1. Make sure you have a good ground connection. This will help to prevent voltage fluctuations and reduce noise.

2. Use decoupling capacitors to filter out high-frequency noise.

3. Use low-ESR (equivalent series resistance) capacitors for your power supply filtering.

4. Place your capacitors as close to the power pins of your ICs as possible.

5. Be careful not to exceed the maximum current rating for your traces.

6. Pay attention to thermal issues, and make sure your components are not overheating.

Conclusion

Properly measuring PDN impedance is essential in ensuring reliable power delivery to your PCBs. This measurement allows designers to understand the performance of their design, identify potential problems and ensure that they are able to deliver adequate power with minimal noise. With all these advantages, it’s clear why PDN impedance measurements should be part of any designer’s toolkit when designing a reliable and efficient power supply for their PCBs.