Ammonium Molybdate Manufacturing Plant Cost 2023-2028: Manufacturing Process, Project Report, Business Plan

How to Set a Ammonium Molybdate Manufacturing Plant:

IMARC Group’s report titled “Ammonium Molybdate Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a comprehensive guide for establishing a ammonium molybdate manufacturing unit. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more. In addition to the operational aspects, the report also provides in-depth insights into project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and navigate the path toward a successful ammonium molybdate manufacturing venture.

What are Ammonium Molybdate?

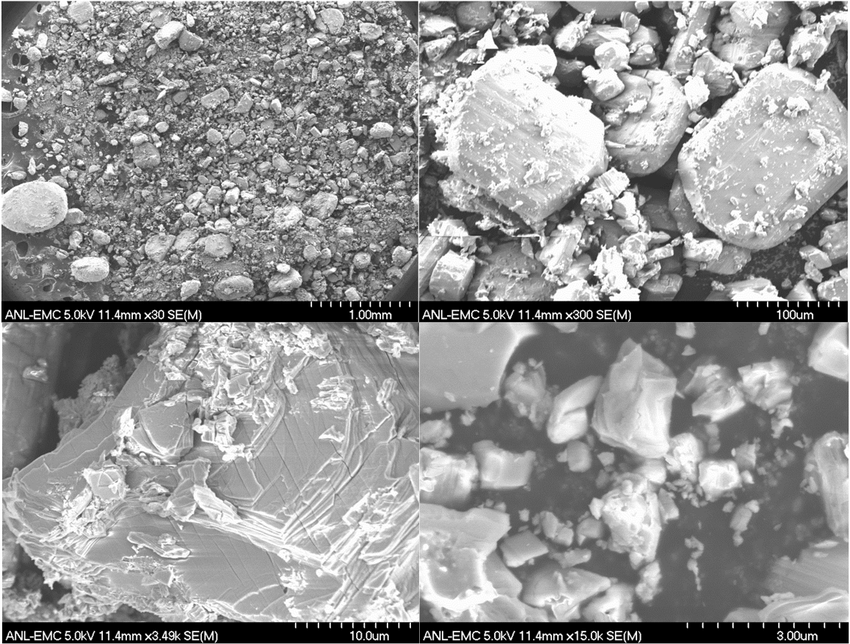

Ammonium molybdate, a pivotal chemical compound, plays a fundamental role across a wide spectrum of industries due to its exceptional properties and extensive applications. Formed by the reaction between molybdenum oxide and ammonium hydroxide, this inorganic salt holds significant importance in realms such as analytical chemistry, catalysis, and agriculture. Its distinctive ability to form highly vibrant complexes with various substances has paved the path for its utilization as a reagent in laboratory experiments, aiding in the detection and quantification of elements and compounds. Furthermore, ammonium molybdate acts as a catalyst in crucial industrial processes and serves as an essential source of molybdenum in agricultural fertilizers, promoting plant growth and augmenting nutrient assimilation.

What are the key market trends and drivers?

Ammonium molybdate has undergone a dynamic interaction of market forces and trends that have significantly elevated its importance across various industries. The increasing demand for advanced materials and technology has notably heightened the significance of ammonium molybdate, especially in sectors like electronics and aerospace. Its diverse functions as a corrosion inhibitor and a crucial component in manufacturing specialty steel alloys for high-stress environments have been key drivers for its demand in these industries. An important trend is the integration of ammonium molybdate in energy-related applications, particularly as a critical element in catalysts used for hydrodesulfurization in petroleum refining. The global emphasis on sustainable energy has further boosted its use in catalytic processes, playing a substantial role in reducing sulfur compounds from different fuel sources. Additionally, the agricultural sector maintains a strong need for ammonium molybdate due to its essential role as a micronutrient present in fertilizers. With the rise of sustainable farming practices, the demand for fertilizers enriched with molybdenum is driven by the necessity for effective nutrient management. The wide range of applications linked with ammonium molybdate, combined with continuous efforts to improve formulations and production methods, points toward a promising trajectory for its growth within the market. As industries evolve and sustainability remains a top priority, ammonium molybdate is well-positioned to maintain its crucial role across various sectors.

Request Sample: https://www.imarcgroup.com/ammonium-molybdate-manufacturing-plant-project-report/requestsample

What aspects are included in the report on setting up a ammonium molybdate plant?

Report Coverage: The project report includes the following information:

Market Analysis Coverage:

- Market Trends

- Breakup by Segment

- Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Outlook

Project Techno Commercial Requirements Coverage:

Detailed Process Flow:

- Product Information

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

Project Details, Requirements and Costs Involved:

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

Project Economics:

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

What Key Questions Does This Project Report Address?

- How has the ammonium molybdate market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global ammonium molybdate market?

- What is the regional breakup of the global ammonium molybdate market?

- What are the price trends of various feedstocks in the ammonium molybdate industry?

- What is the structure of the ammonium molybdate industry and who are the key players?

- What are the various unit operations involved in an ammonium molybdate manufacturing plant?

- What is the total size of land required for setting up an ammonium molybdate manufacturing plant?

- What is the layout of an ammonium molybdate manufacturing plant?

- What are the machinery requirements for setting up an ammonium molybdate manufacturing plant?

- What are the raw material requirements for setting up an ammonium molybdate manufacturing plant?

- What are the packaging requirements for setting up an ammonium molybdate manufacturing plant?

- What are the transportation requirements for setting up an ammonium molybdate manufacturing plant?

- What are the utility requirements for setting up an ammonium molybdate manufacturing plant?

- What are the human resource requirements for setting up an ammonium molybdate manufacturing plant?

- What are the infrastructure costs for setting up an ammonium molybdate manufacturing plant?

- What are the capital costs for setting up an ammonium molybdate manufacturing plant?

- What are the operating costs for setting up an ammonium molybdate manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for an ammonium molybdate manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up an ammonium molybdate manufacturing plant?

- What are the key success and risk factors in the ammonium molybdate industry?

- What are the key regulatory procedures and requirements for setting up an ammonium molybdate manufacturing plant?

- What are the key certifications required for setting up an ammonium molybdate manufacturing plant?